Description

Diaphragm pumps are designed with a diaphragm built-in that moves up and down. The up movement is going to create a suction that is going to pull liquids through the inlet. The downward motion is going to push them through the outlet.

These types of pumps can handle liquids of varying viscosities--liquids with low levels of friction will move through this pump easily; liquids with higher levels of friction will also pass through this pump easily. Liquids with higher viscosities can include water with mud or sludge in it.

All components of this piece that come in contact with liquids being pumped are made from chemically resistant fluoroplastics; these materials make this pump ideal for pumping corrosive gasses or vapors.

This pump has been engineered for performance--it produces flowrates that are 40% higher than pumps with similar free air capacity ratings. It has also been completely redesigned so that it's quieter than its predecessor.

Because this machine doesn't require oil in order to run, the misting, handling, and disposal of contaminated oil has been completely done away with.

| TECHNICAL DATA |

UNIT |

MD 4C NT |

| Number of heads / stages | 4 / 3 |

|

| Max. pumping speed at 50/60 Hz | m3/h | 3.4 / 3.8 |

| Max. pumping speed at 50/60 Hz | cfm | 2.0 / 2.2 |

| Ultimate vacuum (abs.) | mbar/torr | 1.5 / 1.1 |

| Ultim. vac. (abs.) with gas ballast | mbar/torr | 3 / 2.2 |

| Ambient temperature range (operation) | °C | 10 - 40 |

| Ambient temperature range (storage) | °C | -10 - 60 |

| Max. back pressure (abs.) | bar | 1.1 |

| Inlet connection | Hose nozzle DN 8-10 mm |

|

| Outlet connection | Hose nozzle DN 8-10 mm |

|

| Rated motor power | kW | 0.25 |

| Rated motor speed at 50/60 Hz | min-1 | 1500/1800 |

| Degree of protection | IP 40 |

|

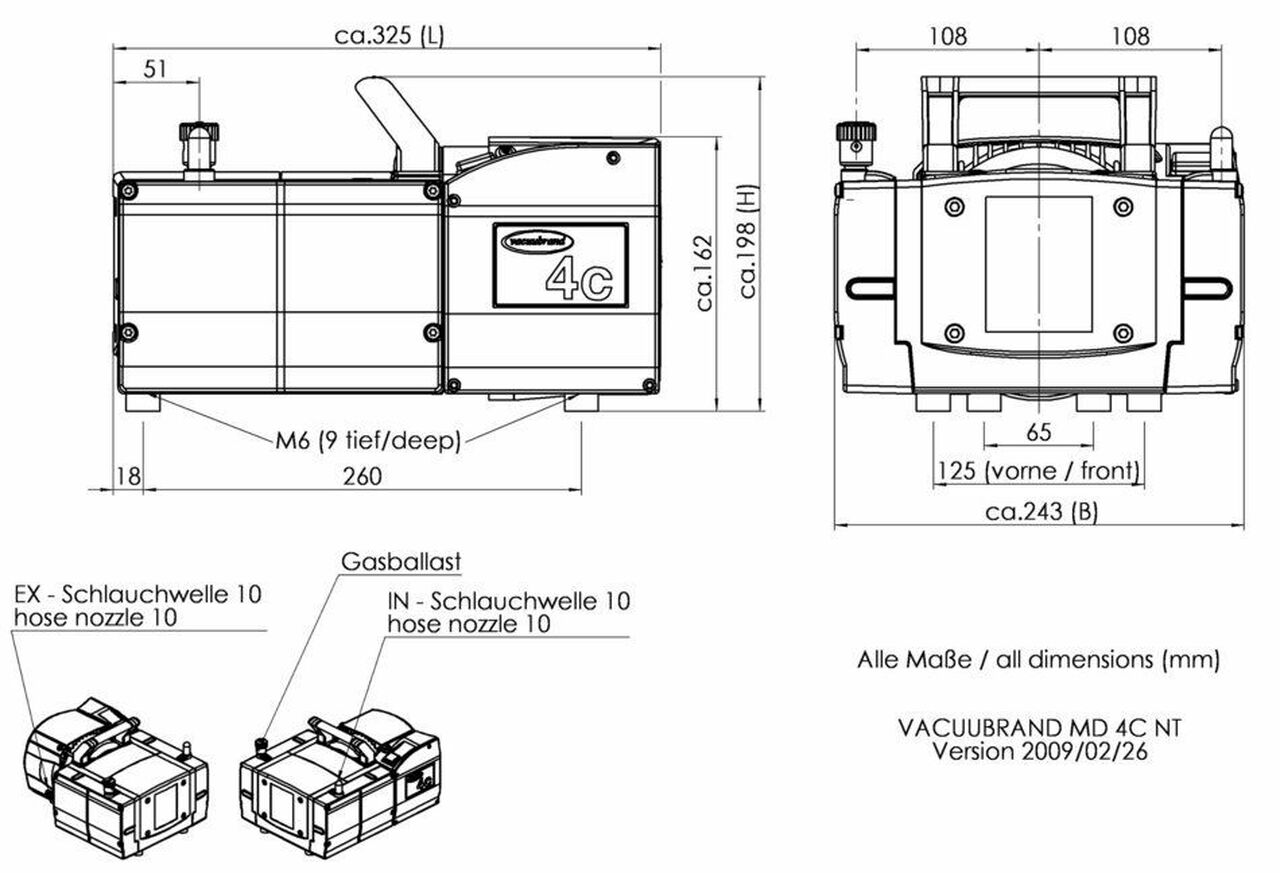

| Dimensions (L x W x H) | mm | 325 x 243 x 198 |

| Noise level at 50 Hz, typ. | dBA | 45 |

| NRTL certification | Canada and the USA |

|

| ATEX conformity (only 230V) | II 3/- G IIC T3 X Internal Atm. only |